This past July, General Motors held a Camaro Open House weekend at the Oshawa Vehicle Assembly Facility which is the only Camaro production plant. Yes, that means every new Camaro you’ve seen on the road was built in Oshawa, Ontario, a city of 150,000 about 40km east of Toronto. It was a fabulous event which included full access to the new and very high-tech Flex Plant assembly facility while production was running. It was the first time I’d seen the plant in production since working as a security guard as a summer student in 1979.

The ‘Flex Plant’ is a modern redesign of the traditional automotive assembly line that allows for the production of up to four different vehicle types on the same ‘line’ at the same time. While we were touring the facility the flex line was producing the Chevrolet Camaro and the Buick Regal. It was interesting to watch as two very different vehicles would roll off the line one after the other. General Motors recently announced that they will be adding a new full-sized Cadillac to the flex line next year.

Since beginning Camaro production a couple of years ago, more that 250,000 vehicles have been produced. Most of the Camaros have been coupes however with the introduction of the roadster last year a lot of convertibles are now being built. I must admit to a strong bias as I’ve owned Camaros in the past, but to put the production numbers into perspective, between April 2009 and May 2010 General Motors sold 100,486 Camaros while Ford sold 87,670 Mustangs and Chrysler sold 30,521 Challengers.

It was a rare pleasure to be allowed to take pictures of the cars being assembled and I trust you enjoy the images that follow. Most were taken with the 24-105mm f/4 EF L lens to take advantage of the image stabilization however I also used a 16-35 f/2.8 EF L lens as well.

The old and the new!

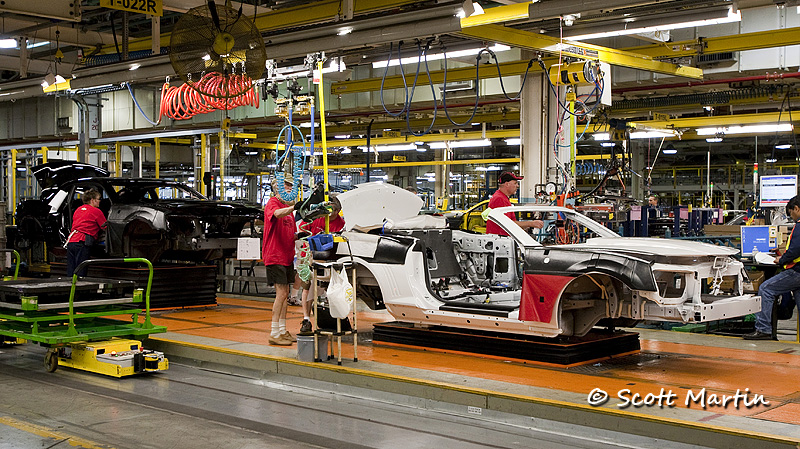

The process begins (coupe first followed by a roadster).

.

Meticulously checked for surface defects before being sent to the paint shop.

.

They look better painted!

.

The following image shows the attention to ergonomics that is taken to reduce work related injuries and increase production efficiencies. Note how the chassis rests on a large bellows platform that raises and lowers as it moves through the facility maintaining the optimal height for the workers to safely carry out specific tasks for that part of the assembly process. Notice the white vehicle is much lower than the black one in this shot.

Although these are V6 engines destined for the Buick Regal (the open house didn’t allow access to the Camaro engine line) it’s an example of the many production design intricacies required to efficiently assemble a car today.

While the chassis is being developed in one area the power train is being assembled in another. You’ve gotta love that dual exhaust!

Completed power trains sitting on computer guided platforms ready to be mated with their chassis. This process is almost fully automated and it was incredible to watch as everything lined up perfectly every time! I’ve tried to capture the process in the next few images which show the power train moving into place beneath the chassis, raising into place and then the empty platform leaving to go back and get fitted with another power train. The entire process takes about five minutes per vehicle.

.

.

.

.

Notice the car behind the yellow Camaro is a Buick Regal.

Tires are one of the last things to make their way onto the vehicle.

.

Another Camaro comes to life!

Coming off the line.

.

I couldn’t resist attempting a few artistic shots, even in a vehicle assembly plant. I hope you enjoy them!

.

Camaro Car Clubs from all across North America came to the open house. There were over one thousand Camaro’s of every year and model at the event. It was a treat to walk among the cars, chat with the owners and hear the many stories behind each car. I think its time to buy another Camaro!

Great post Scott! It is a rare insight into what goes into the production of a modern vehicle. Based on the production numbers, I must conclude that most of the Camaro’s must be going south since I see more Challengers on the road than Camaro’s 🙂

Thanks Arni and this is the first thing I’ve done on the new iMac….liking it so far 🙂